Ben Freelove flies his Edge 540 equipped with the iEFIS Explorer 8.5-inch touchscreen from MGL Avionics. |

On the face of it, the subject of engine analyzers isn’t very enticing. Engine monitors aren’t “sexy” like digital flight instruments or GPS displays. They’re not exciting like angle-of-attack indicators or G-meters. But get a pilot talking about engine failures in flight (especially on takeoff), and engine analyzers become like the most popular girl at a dance. That’s because monitoring an engine’s health—like monitoring our own—is what determines everything else. You can’t have fun with a G-meter if the propeller isn’t turning.

Experts have proven that engine failures—be they piston or turbine—don’t simply “happen” without warning. Even my stalwart mechanic who has been turning wrenches for over 40 years promises that engines give you ample hints before they completely fail, and that it’s up to us as pilots to notice the subtle warnings that occur over time. Those hints come to us via engine analyzers.

With 100LL fuel prices hovering ever closer to $7 and $8, economy and efficiency become additional key factors for the average general aviation pilot. It’s here where engine analyzers prove their mettle. There have been endless articles about operating lean-of-peak or rich-of-peak and what benefits each offer. There are also countless combinations of fuel flow and power that offer the best performance for a given trip. The only effective way to really dial those settings in is to have an accurate engine analyzer that allows precise control over performance parameters. Enter today’s digital engine monitors.

In decades past, owners of basic general aviation aircraft didn’t have much in the way of technology to help them monitor an engine’s health or performance. In the 1960s, we started seeing more CHT (cylinder head temperature) and EGT (exhaust gas temperature) gauges in GA aircraft. But these were mostly luxuries and weren’t standard in most aircraft. Also, most were calibrated fairly coarsely, or they monitored only a single cylinder, so true engine analysis was difficult or impossible. But, today we have a slew of engine analyzer instruments that display so much detailed data they rival emergency room monitors for humans. Engine analyzers are one of the best—and most reasonable—investments you can make in your airplane.

Alcor |

Alcor

www.alcorinc.com

Alcor manufactures a line of round-dial, small-footprint engine gauges that are ideal for vintage aircraft where panel space is limited and advanced features aren’t necessary. Their line of gauges have a beautiful simplicity about them, yet they’re precise enough to allow fine control of performance parameters. Specializing in CHT, EGT and TIT (turbine inlet temperature), Alcor offers a wide variety of instruments that combine the different parameters, and they’re available for single and multi-engine aircraft.

While humble EGT and CHT sensors don’t have the “wow” factor of digital displays, Alcor has made its reputation from more than 50 years of installation in demanding environments. Alcor units are renowned for their reliability, durability and affordable price. Alcor probes are also some of the most robust in the industry and can also power sophisticated glass systems. The blanket Supplemental Type Certificate (STC) held by Alcor allows for the installation of their probes in any aircraft with a reciprocating engine without additional paperwork.

Avidyne |

Avidyne

www.avidyne.com

Avidyne’s Entegra integrated flight deck is one of the most beautiful displays in aviation. All that panel real estate makes for a clear and imposing display. Avidyne’s latest Release 9 flight deck includes the EMax Engine Monitoring system as its integrated engine analyzer, though it’s much more than that. EMax is a dedicated engine page with an avalanche of performance data, including a handy graphical fuel totalizer, a lean assist mode and a percent power display to take the guess work out of fuel and power management.

EMax monitors fuel flow and computes nautical miles per gallon, fuel remaining, fuel to waypoint and fuel to destination. Temperatures, pressures, RPM, fuel flow, OAT, and electrical bus voltages are also monitored and displayed. The integrated fuel totalizer monitors fuel flow and computes nautical miles per gallon, fuel remaining, fuel-to-waypoint, and fuel-to-destination. All CHT and EGT, RPM, manifold pressure, oil temperature, oil pressure, fuel flow, outside air temperature (OAT) and electrical bus voltages are monitored and displayed.

Our favorite feature is “lean-assist.” Once cruise power is established, press the “Lean Acquire” button. As you lean the mixture, the engine monitor continually checks all cylinders for the first cylinder to achieve peak EGT. “Peak EGT” is annunciated when the first cylinder to peak is detected. The cylinder column color also changes from green to blue and shows peak temperature. We also like how Emax shows a clear indication when “best power” or “best economy” has been properly set. Avidyne’s EMax works with single or multi piston and turbine engines.

Dynon |

Dynon

www.dynonavionics.com

Dynon Avionics’ EMS-D120 is a large-screen stand-alone Engine Monitoring System (EMS). The unit replaces up to 16 different types of gauges and features a crisp and bright seven-inch (diagonal) color screen. The sunlight-readable color display and soft-key menu system is easy to use and intuitive enough for in-air manipulation. The EMS-D120 can monitor up to 27 sensor inputs, which covers all the engine, fuel, electrical and other systems the pilot would want to see. The unit annunciates any abnormality immediately upon detection, making it easy for the pilot to focus outside the cockpit.

The EMS-D120 is easy to set up and configure, with a handy split-screen display that allows an overall summary of the engine’s performance along with additional pages of auxiliary information on demand. The display can be customized to an impressive degree and, along with configurable checklists, provides a lot of information and flexibility.

Pilots wanting an engine monitoring system that integrates with an EFIS in a single unit should consider the Dynon FlightDEK-D180. Combining both electronic flight information as well as engine data, the FlightDEK-D180 provides both on a split-screen, seven-inch display, making it an efficient panel space saver. In addition to all the functions of the EMS-D120, the FlightDEK-180 adds attitude, airspeed, altitude, vertical speed, gyro-stabilized magnetic compass, slip/skid ball, turn rate, clock, timers, G-meter, and HIS, all from Dynon’s advanced ADAHRS (Air Data, Attitude and Heading Reference System).

Electronics International

www.buy-ei.com

Electronics International manufactures their impressive line of engine analyzers in the U.S. They make a dizzying array of engine instruments, which are their sole specialty. They range from single-hole, EGT gauges for homebuilt aircraft to their impressive MVP-50P “glass” engine monitor and analyzer. They have something for every aircraft and every budget.

Electronics International |

The company’s flagship MVP-50P is an impressive unit. STC’d and TSO’d, the 5 ½-inch panel-mount glass display offers 15 screens of information and over 50 functions – almost all of them customizable. The MVP-50P allows pilots to accurately monitor dozens of engine and system parameters, program redline limits, setup custom inputs, create interactive checklists, store general flight information, build flight plans, record and review pertinent data from every flight, finely monitor performance, track an engine’s health and more. The displays are aligned with the aircraft’s throttle and prop controls and provide both analog and digital displays. The digital display provides accurate detection of small trends. The analog display provides field of vision, allowing the pilot to determine a function’s position in its operating range.

The MVP-50P comes standard with a full-featured color bar graph to assist with rich-of-peak and lean-of-peak engine leaning. One of our favorite features of the MVP-50P is the “peak marker,” which tracks your engine’s history. This unit’s bar graph keeps track of where the cylinders peaked during each leaning process. On subsequent flights, the unit displays a peak marker indicating where each cylinder peaked during the previous flight, allowing close detection of minute differences and showing possible problems long before they create a hazard.

Garmin |

Garmin

www.garmin.com

Garmin’s game-changer G1000 glass cockpit (and now G2000/G3000 and G5000, depending on aircraft type) includes a full-featured engine monitoring system. Whereas Avidyne has a single engine summary page, Garmin spreads engine data among three panels on the MFD (multi-function display), though the G1000’s “System” panel includes all the basic information. Garmin’s engine monitor includes an all-cylinder graphical EGT with a lean assist function, as well as an all-cylinder CHT. Electrical system health (alternator and battery information), along with fuel flow, fuel quantity, oil pressure, oil temperature and manifold pressure are displayed. Fuel totalizers track fuel consumption and remaining fuel.

One of Garmin’s best enhancements since introducing the G1000 has been the ability to save performance data. Residing on the MFD’s SD card, the data can be saved and monitored for trends and detection of problems. Garmin has developed a great little free tool to analyze the data from the G1000 called the Integrated Flight Deck Engine Data Analyzer. It’s essentially a Visual Basic macro written for Microsoft Excel, and designed to enable owners of turbine-powered aircraft to log and analyze engine data in a graphical way. It’s available from Garmin’s website. For piston users, Savvy (an aircraft maintenance company) offers an online analyzer for Garmin’s data. You can upload your data for free at www.savvyanalysis.com. Also, EGTrends offers a comprehensive analyzer and charter for G1000 data at www.egtrends.com. For more information on Garmin’s engine monitoring features, visit www.garmin.com/en-US/explore/intheair.

Insight Avionics |

Insight Avionics

www.insightavionics.com

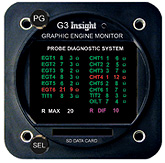

Insight’s vast line of graphical engine monitors promises something for everyone. The beauty of their design is that, instead of a square display, the Insight instruments fit into either a 2¼-inch or 3¼-inch panel hole. But that tiny space is brilliantly engineered to display an enormous amount of data in an intuitive and clear fashion. Insight’s flagship analyzer is the G3 Graphic Engine Monitor.

The unit packs Simultaneous EGT, CHT, TIT, bus voltage, instrument vacuum, fuel flow, fuel used, alternator temp, OAT, manifold pressure, RPM, oil temp and oil pressure into several “pages” within the single display. Pages are accessed through a simple knob on the front. It couldn’t be simpler. Our favorite feature is unique to the Insight instrument: a detailed vibration analysis page that allows the pilot to safely operate lean-of-peak. The feature detects early-stage mechanical problems to prevent catastrophic engine failures. The G3 performs sophisticated data logging, storing a slew of performance data on an SD card accessible from the face of the unit. It even includes an integral fuel computer with GPS fuel interface. Software updates are done over the web. It’s a brilliant instrument.

JP Instruments |

JP Instruments

www.jpinstruments.com

Based in Huntington Beach, Calif., JP Instruments helped pioneer the digital engine instrument market when founder, Joseph Polizzotto—an engineer for Pratt and Whitney—made his own engine temperature scanner for his Cessna 172. Demand for the instrument was so big that Polizzotto started a company in 1986 to market them. Today, the company still offers that first monochromatic scanner, along with some of the most respected engine instruments in the industry.

The company’s EDM 830 (EDM stands for “Engine Data Management”) is one of the most comprehensive engine analyzers out there. Fully TSO’d, the EDM 830 is a square, color LCD panel display that monitors EGT and CHT, voltage, fuel flow (used and remaining), endurance, manifold pressure, oil temp and pressure, OAT, and %HP. JPI’s Leaning Mode is a great tool for fine adjustment of LOP or ROP performance. We love the unit’s ability to monitor for shock cooling, something few analyzers offer. For more complex environments, JPI offers their flagship EDM 930 with even more features, more monitoring parameters and certified as a primary display.

MGL Avionics |

MGL Avionics

www.mglavionics.com

MGL specializes in digital instruments for the LSA and homebuilt market. Their instruments are models of capability and affordability. The California-based company is unique in that all the technology design is done in-house, while many parts are sourced in South Africa. In business since 2000, their line of EFIS displays and digital instruments is impressive and broad.

MGL’s full-featured XTreme EMS is a full-color comprehensive engine monitoring system. Four- and six-cylinder engines are supported, with up to 12 total channels of CHT or EGT available in any combination. Two fuel level inputs are available, and the unit displays fuel flow, battery voltage, OAT, MAP (manifold pressure), RPM, and several timers include a Hobbs meter. The 4.3-inch sunlight-readable, wide-viewing angle, high-resolution LCD display is easy to read and includes alarms on critical parameters. It integrates an SD card reader for software updates and for engine data recording, five function buttons and a rotary control. Our favorite feature is the fact that the whole thing fits into a standard 31â8-inch panel hole.

Ultra Electronics |

Ultra Electronics

www.ultra-fei.com

Ultra’s AuRACLE line of engine management systems provides pilots with primary engine management data compatible with 95% of all single and twin-engine general aviation aircraft. In addition to common monitoring parameters like fuel data, EGT and CHT, voltage and ammeter, OAT, manifold pressure and oil information, the AuRACLE line offers a useful %HP display.

Ultra’s CRM 2101 is certified as a primary display and includes advanced features like 150 hours of performance data logging, flight data transfer via USB and their SmartLean⢠intuitive leaning process. Our favorite feature is the EGView software included with the unit. EGView allows you to download your archived engine data and examine it using colorful graphs and data displays and track countless performance parameters. Designed to compete head-to-head with the JPI EDM 930, the CRM 2101 fits into the JPI’s wiring harness without modification.