Improving On A Good Thing

The venerable Cessna P210N enjoys a welcome improvement

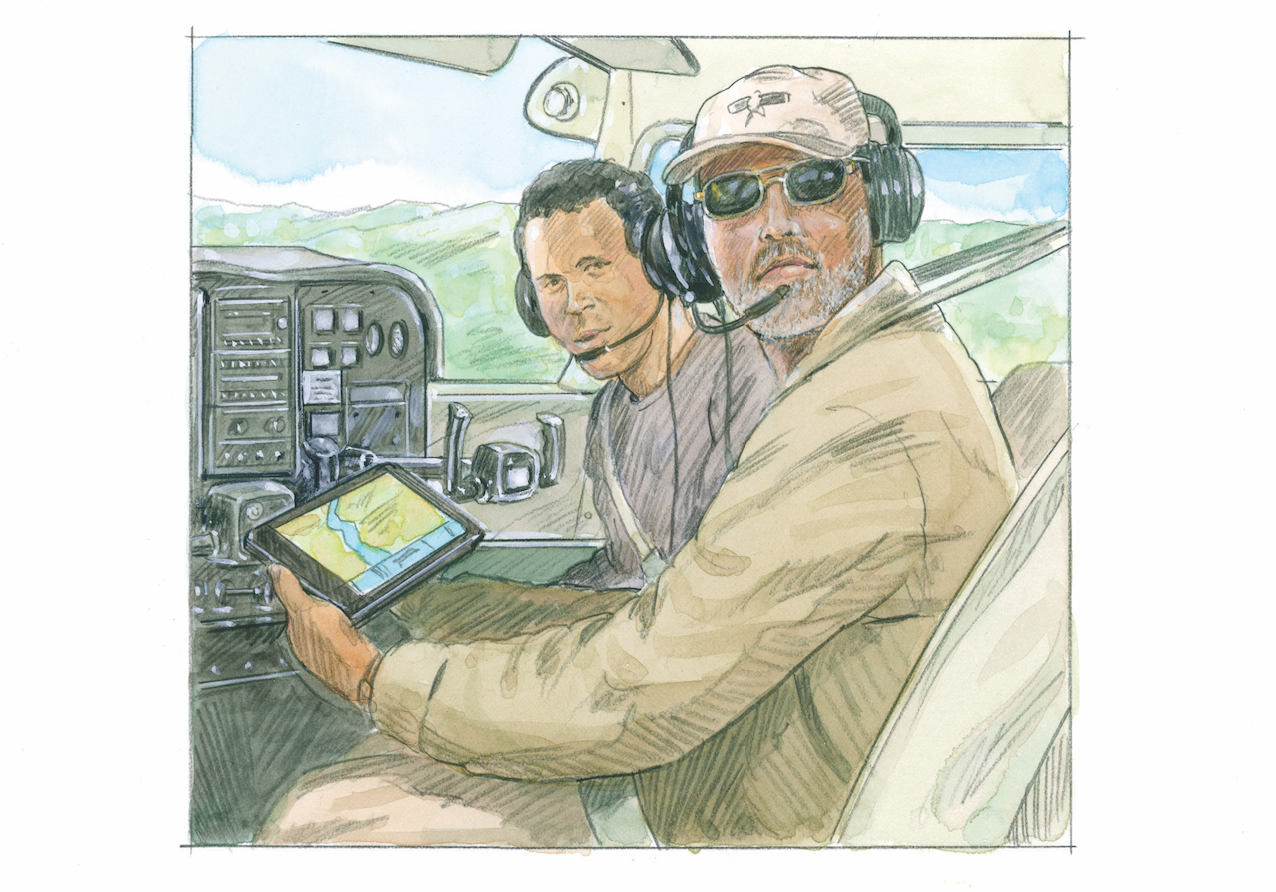

CESSNA P210N. Larry Vitatoe's Centurion conversion uses a factory-new Continental IO-550P engine with the 520's stock turbocharger, and adds dual intercoolers and a larger alternator. |

Just as airplanes such as the straight-tail Beech Bonanza and Piper Super Cub have become pre-eminent in their respective classes, the Cessna 210 has enjoyed a similar reputation as an aviation icon.

Like the models above, the Centurion has hundreds of devotees who love their airplanes and wouldn't think of flying anything less. In the Centurion's case, the pressurized P210N was one of Cessna's most popular models, with over 800 sold in only five years. Like power windows, power steering, power seats and power brakes in a car, pressurization is one of those conveniences that's hard to live without, once you've adjusted to living with.

The total unquestionably would have been greater except for the airplane's short production life and some not-so-niggling problems on the early models. The P210 had the distinction of being the first successful pressurized single. Mooney offered the five-seat M22 Mustang in the late '60s, but the airplane was overweight, often ran hot and was perhaps too far ahead of its time. Mooney discontinued the Mustang after building only 36 M22s during a short, four-year production run. All 36 Mustangs were sold at a loss, and that undoubtedly contributed to Mooney's 1969 bankruptcy.

The first P210N was introduced as a 1978 model and also suffered an abbreviated life, eight years, though not necessarily because of its operational shortcomings. In 1985, Cessna president Russ Meyer ordered all piston models discontinued until congress could pass a reasonable statute of liability repose.

Though the P210's concept was outstanding, the execution was flawed. It seems there's always a, "Yeah, but!," waiting in the wings. Like every design, even aviation's most popular models have their share of flaws. The original P210Ns had some significant engine and system problems. Two of the early airplanes crashed, and the NTSB attributed both accidents to detonation from super-lean mixtures. The high temperatures associated with attempting to run the 210s at book-mixture settings caused extremely high CHTs that resulted in premature cylinder failure and exhaust cracks.

The FAA mandated extra-rich mixtures, about 21 gph at max cruise, and that resulted in higher fuel burns and lower performance. In May 1981, Cessna introduced a new turbo that was supposed to solve the problem but didn't. Instead, it reduced performance even more, forcing pilots to fly at lower altitudes and lower true airspeeds.

Cessna finally found a partial answer in late 1981 with a new induction system that utilized a larger intake scoop and redesigned air plenum. This added seven inches of manifold pressure, solved some of the P210N's problems, but not enough.

The 1984 Piper Malibu knocked the Cessna P210N completely out of the box. Cessna chose to withdraw the airplane from the market and reconfigured everything from the power plant to the wing and horizontal tail. As a result, there was no 1984 model P210. Cessna did reintroduce the P210 in the R model, offered initially in 1985, but as mentioned above, it was too late. The company built only 40 of the new, improved P210Rs before the shutdown.

Larry Vitatoe of Chillicothe, Ohio, had a better idea. Vitatoe owns a '79 P-Centurion that had many of the same problems. Why not, he reasoned, replace the P210N's Continental TSIO-520P with a factory-new, Continental IO-550P, mount the 520's stock turbocharger, add dual intercoolers, a larger alternator and wind up with an engine that would run smooth and cool at 50 degrees lean of peak, burning at least three gph less fuel.

In the process, the 210 would benefit from a six-point engine mount, providing smoother power delivery. Vitatoe also chose to install a semi-scimitar 80/82-inch Hartzell prop. The conversion would work equally well on the P210 and the T210, since both airplanes employ essentially the same engine.

Vitatoe used his aircraft as the prototype and was well pleased with the results. By running the engine at 50 degrees lean of peak, he realized a dramatic reduction in cylinder head temps, and fuel flow dropped to about 17.6 gph at high cruise, 30 inches and 2,500 rpm. Also, more than incidentally, the bigger Continental is rated for a 2,000-hour TBO, at least 400 hours longer than the stock 520. Horsepower remained at the original 310, but virtually every performance spec improved.

Vitatoe and I ferried one of the first of the conversions, a T210N, from Chillicothe to St. Petersburg, Fla., late last year, and in early April, I delivered a second Vitatoe conversion, a P210N, to San Jose for owner Michael Hsing, CEO of a major Silicon Valley IT company. Neither trip provided favorable winds up high---in fact, we faced 70-knot headwinds at times---but true airspeeds were 185 knots at 14,000 feet.

That second delivery was perhaps more typical of the standard conversions, as it involved a pressurized model. "I intended the conversion specifically for the P210," says Vitatoe, "but the turbocharged airplane employs the same engine and doesn't include all the extra plumbing, valves and reinforcement associated with the pressurization system. As a result, it offers about 180 pounds better payload."

I flew the second delivery with Dr. Ray Landes on board, owner of a T210 that was in Vitatoe Aviation's shop for the upgrade. Landes wanted some firsthand practice with the engine, and he monitored power throughout our short, two-day, 1,900 nm trip. Landes kept careful watch on cylinder head temps and EGTs, and he maintained the former at a maximum 380 degrees and the latter under 1,550 degrees. If either temperature began to climb above acceptable parameters, standard procedure was to lean the engine slightly to reduce the heat, or in the worst case, to open the cowl flaps a notch.

That's exactly the opposite of the philosophy most pilots have embraced for years, and it takes a little attitude adjustment to wrap your head around the updated technique. If you run 50 degrees rich of peak and temperatures are too high, you richen up the mixture to bring them down. Running lean of peak, you do exactly the opposite.

Contrary to what you may be thinking, this is far from a new technique. A guy named Lindbergh used it on his solo, 1927, Atlantic crossing from New York to Paris, and later taught the technique to American P-38 pilots in the South Pacific during WWII. (This may have contributed to the long-range, P-38 mission that resulted in the death of Japanese admiral Isoroku Yamamoto at Bougainville, Solomon Islands, in April 1943.)

More recently, George Braly and Tim Roehl of General Aviation Modifications in Oklahoma championed lean-of-peak operation, primarily on Continental IO/TSIO-550 engines. Despite the evidence that lean of peak works, Braly and Roehl have been fighting an uphill battle to popularize the leaning method, and they've finally gained pilot acceptance in the industry.

Ray Landes and I launched, hoping to climb into the lower flight levels and see what the airplane could do. The smoothness of the IO-550 was immediately obvious, and lean-of-peak operation proved almost idiot-proof.

The trip turned out to be anticlimactic because of headwinds as high as 70 knots and thunderstorms over the Rockies and Sierra Nevada. We delivered the airplane two days later to Reid-Hillview Airport in San Jose, recording a max cruise of 190 knots TAS at a low 14,000 feet on the final leg from Long Beach to San Jose. Larry Vitatoe has seen 212 knots above 20,000 feet, and I believe it. That's about the same performance claimed for the redesigned 325 hp Cessna P210R.

Vitatoe Aviation is currently working on conversion number 16, and if our experience with Mike Hsing's airplane is any example, Vitatoe and company should have many more to look forward to. For more information, write to larry.vitatoe@vitatoeindustries.com.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox