Money-Saving Maintenance

A forum of experienced A&P mechanics and IAs pass along tips to preserve the value and airworthiness of airplanes in the most cost-effective way

Those pilots who have ever found themselves paying huge chunks of money on maintenance bills know that they can get quite expensive. What most people don't realize, however, is that there are other simpler and less expensive ways to save on aircraft maintenance bills---and it all starts with the aircraft owners and operators themselves. Just take a look at some mechanics' advice on how you can prevent that dreaded maintenance bill from ballooning. The money you save in the end will be well worth it.

Those pilots who have ever found themselves paying huge chunks of money on maintenance bills know that they can get quite expensive. What most people don't realize, however, is that there are other simpler and less expensive ways to save on aircraft maintenance bills---and it all starts with the aircraft owners and operators themselves. Just take a look at some mechanics' advice on how you can prevent that dreaded maintenance bill from ballooning. The money you save in the end will be well worth it.

It may surprise you, but the first and foremost thing that any aircraft owner and operator can do is to make sure that their aircraft has a complete set of logbooks. It's a 100% owner and operator responsibility (according to FAR Part-91) that doesn't always get the adequate attention that it needs. All records and logbooks need to be treated as someone would a wad of $1,000 bills because that's what they essentially equate to. Nothing much else can certify the condition, quality and worth of an airplane. The value of any kind of airplane can be increased or drastically reduced based on the quality, condition and contents of these records. So don't underestimate the importance of keeping records up to date, orderly and secured.

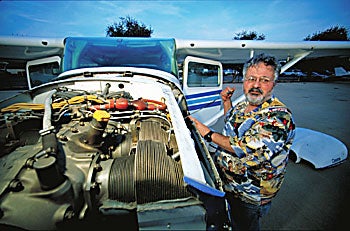

In a recent discussion with some A&P mechanics and IAs, changing the engine oil on a regular basis was their number-one response to what aircraft owners should do in order to prevent costly repairs and achieve maximum engine service life. Engine oil becomes contaminated with acids, water, carbon, metals and other contaminants through normal use and flying, which can cause accelerated wear and deterioration. How often to change the oil depends on the conditions under which the aircraft is operated, but a general rule is every 50 hours for aircraft equipped with a full-flow filter, and every 25 hours for those with only an oil screen, or every four months, in any case.

Next on the list, as elementary as it may seem, is to keep your airplane clean and waxed. A clean aircraft looks nice, but there are several more valid reasons to keep it that way. Dirt and grime on airframe surfaces, around rivet heads and in seams hold moisture that invites corrosion to set in. A clean, waxed aircraft also is more aerodynamic and allows easier detection of defects and leaks. Keeping an aircraft clean and waxed should be a regularly scheduled maintenance task and shouldn't just be something to do when you have some spare time. After washing an aircraft, it should be greased and lubricated, and the pitot static ports should be checked for obstructions. While you're at it, thoroughly inspect the whole aircraft for any deep scratches or abrasions, and if any are found, take care of them as soon as possible. At a minimum, sand down the area to remove any roughness or burrs, and touch it up with paint. This is important because most aircraft are constructed primarily of 2024-T3 aluminum, which has a thin cladding of pure aluminum on its outer surface that resists corrosion, but the cladding is just a couple thousandths of an inch thick. Below that layer is an alloyed metal that's susceptible to corrosion. A deep scratch exposing the alloyed metal can eventually cause measurable harm and be expensive to repair. Keep in mind that corrosion is irreversible, and that surface protection is the best method of preventing it.

Taking good care of the aircraft records and logs, changing the engine oil and keeping an airplane clean and waxed are three fundamental actions that every owner can take to maximize his or her aircraft's service life. If you're the type who wants to get serious about maintaining your aircraft in tip-top condition and avoid costly unscheduled maintenance expenses, however, there's much more that can be done. FAR Part 43 authorizes holders of a private-pilot certificate under Part 61 to perform preventive maintenance on any aircraft that is owned and operated by that pilot, as long as it isn't used under Part 121, 127, 129 or 135. It also provides a real thorough list of more than 30 preventive maintenance tasks that can be accomplished as long as they don't involve complex assemblies. Remember that the key words here are "preventive maintenance"---which actually means maintenance tasks that are done to prevent wear and deterioration. For one thing, you can change your engine oil yourself for a fraction of what it costs to have it done.

You also can service all hydraulic shock struts, clean and rotate spark plugs to increase their service life, replace fuel filters, lubricate and grease almost any surface, change tires, make repairs to cracked fairings, clean up the battery compartment, replace light bulbs and safety wires and repair landing-light circuits. A year is too long of a time to go in between inspections, especially with items that require preventive maintenance during the year. Remember, for an airplane to be considered legally airworthy, it must conform to its type certificate, have all required ADs and inspections up to date and be in good condition, which means that the aircraft must be maintained between inspections. For example, a plane that makes many flights or touch-and-goes during the year should have its landing gear lubricated. So how does one learn how to do these tasks?

First of all, you must review FAR Parts 91 and 43. Then, buy a service manual for your aircraft. Next, start an account with an aircraft parts supply distributor and buy the company's catalog. Once your account is established, you can order parts and supplies via the Internet and receive them in a couple of days. Start out by learning to do the simpler tasks. Buy a roll of .032 safety wire (which will, by the way, last a whole lifetime) as well as some inexpensive safety-wire pliers. Read up on safety-wiring techniques in the supplier's catalog, your aircraft's service manual or any basic aircraft maintenance textbook. It shouldn't take you too long to master the art. Once you do, you'll be able to keep all the safety wire in your aircraft in good condition. The next step is order the oils and lubricants that are specified in the service manual and then start lubricating your own aircraft as prescribed by the manual. As you gain knowledge and confidence in your burgeoning maintenance skills, you'll only need a few more tools to be able to start changing your own engine oil with some assistance or training during the first time or two. As your knowledge about preventive maintenance grows, you can then learn to perform almost every aircraft repair that is authorized by FAR Part-43 and applies to your own airplane. But don't forget that every task that you've accomplished requires an entry in the appropriate logbook in order to return the aircraft into service. It has to contain a description of the work performed, the date, your signature and the type of pilot certificate you hold.

And yet another good idea is to conduct a mid-annual aircraft inspection yourself, of course, only to the extent in which you're authorized to do, by using the checklist in your own service manual. Make a list of discrepancies, and try to correct them when you can. When it comes time for the annual inspection, you'll find that the aircraft will be in a much better condition. You also can arrange to assist the aircraft inspector during the annual inspection by removing any items like cowlings, performing lubrication requirements, changing the engine oil, greasing the wheel bearings and repairing any broken or loose safety wire. You'll save money and time by doing this. If any kind of defect is found during the inspection that require a certified mechanic to make repairs, you can order the parts and supplies needed through your aircraft supplier's catalog and provide them yourself, making the repair less expensive. You just need to ensure to check the catalog part numbers against those listed in your aircraft's service manual to make sure they're authorized replacements.

So, in essence, in order to preserve the value and airworthiness of your airplane, you need to maintain all of your records, keep the aircraft clean, change the engine oil, perform as much or as many of the FAR Part-43 preventive maintenance tasks as possible and keep the plane in good condition. There might be some investment and a little work involved, but in the long term, regular upkeep doesn't cost a thing---it pays.

Subscribe to Our Newsletter

Get the latest Plane & Pilot Magazine stories delivered directly to your inbox