|

Aircraft ignition systems are one of those things that few pilots give much thought to. We turn the key, the prop turns, the engine catches, and we’re off for another day of flying. We know that the engine keeps running based on electrical current, but many of us are confused as to the actual role of batteries, magnetos, spark plugs and all the rest. It probably wouldn’t make pilots feel much better to know that the system that keeps them safely in the sky is strikingly similar to the one that runs their lawn mower.

Even if you’re not mechanically inclined, knowing how ignition systems work is critical to safety in the air. You’ll need to know when it’s time to head for the shop, and what to look for during preflight and routine inspections. Before you decide all this might be technical and unnecessary, know that in his autobiography, Chuck Yeager attributed much of his success as a pilot to his understanding of aircraft systems. To assist us in our explanation, we talked to Josh Christopher, Senior Piston Products Engineer for Champion Aerospace.

The Pieces

“Even though we’ve made them more reliable and efficient, the basic design of these ignition systems hasn’t changed much since the ’60s,” says Christopher, “and much of the technology is from over 100 years ago.” But before you start calling it “outdated,” you have to realize that the ignition systems used today are the way they are because they’re proven, incredibly reliable and safe. Like fabric covering, wood spars and rubber tires, ignition systems haven’t changed much because they’re great at what they do.

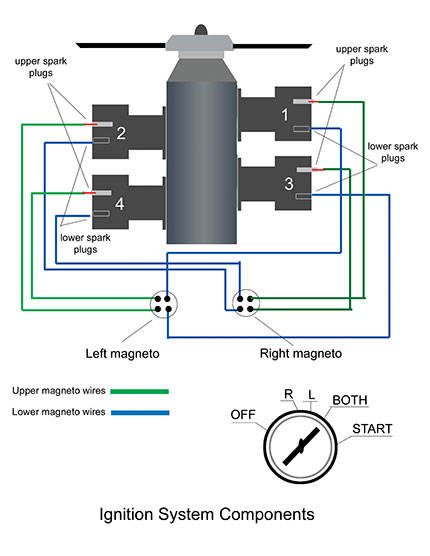

Starting inside the cockpit, your ignition system consists of a starter switch (can also be called a “mag switch”), two magnetos, a wiring harness with leads (wires) going out to each cylinder, and finally, spark plugs. The starter and battery are—believe it or not—unnecessary parts of your ignition system, and there are plenty of Cubs, Luscombes, Taylorcrafts and many other airplanes out there to prove it, but we’ll include these parts in our explanation since modern aircraft are equipped with them.

Turning the master switch “ON” sends electrical current flowing from the battery to the starter. It also “un-grounds” the magnetos—think of them as electrical generators—opening a path for electrical current to flow within them. Turning the key to “START” engages the starter, causing it to turn.

Your starter connects to your propeller through a gear so the propeller turns. This is connected to your engine’s crankshaft, so it turns, too. The crankshaft turns a rotor inside the magneto, producing a high-voltage electrical pulse that goes out through the wiring harness and into the spark plug in each cylinder. That spark ignites the fuel-air mixture, and your engine is alive! At this point, the starter and battery can be thrown away, and your engine would keep running just fine (lawn mowers don’t have batteries or starters, and they keep running too). Without a starter or battery, hand-propping takes the place of the starter, turning the propeller a little bit to get the magnetos firing. The alternator uses the turning engine to generate electricity, and stores it in the battery to run things like radios and lights, but it has nothing to do with running the engine.

The magneto acts as a generator, providing electric pulses to the spark plugs through the wiring harness. |

Once the engine is started, it becomes almost like a perpetual-motion machine; the engine turns the magnetos that produce another spark, which turns the crankshaft, which is attached to the propeller, and it goes on and on, thousands of times per minute until the fuel runs out. Turning your key to “OFF” interrupts the electrical flow through the magnetos, and grounds them through a wire called the “P-lead” (the “P” stands for “primary lead”) that runs from the magneto to the ignition switch. That stops the high-voltage pulses from reaching the spark plugs, effectively stopping the engine.

You now can see why your instructor taught you to momentarily turn your key to “OFF” then back “ON” to see if the engine started to die. That’s to check the condition of the P-lead. If the engine didn’t momentarily hesitate, it would mean the P-lead was faulty and didn’t ground (turn off) the magnetos. Thus, even if the key was turned to “OFF” or removed entirely, moving the propeller by hand (such as during a preflight inspection) would cause it to generate an electric pulse from the ungrounded magneto to the spark plug, starting the engine with you standing in the propeller arc.

Star Of The Show

The star of the entire ignition show is the magneto. In addition to lawn mowers and other small motors, magnetos were used in the earliest telephones to generate the ring. They’ve been around since English physicist Michael Faraday presented his law of electromagnetic induction in 1831. The principle of the magneto goes back to your high-school science class, where you discovered you could create magnetism by wrapping a coil of wire around a piece of iron, and running an electrical current through that coil (from a battery). This was called an electromagnet.

Magnetos work on the opposite principle; a magnet rotated near a coil of wire creates an electrical current. Inside your magneto casing are several components. First is a rotor that turns when your engine’s crankshaft turns. A strong magnet is built into that rotor, with a north and south pole (like all magnets). Above the rotor (parallel to the rotor’s rotation) is a piece of iron wound with about 250 turns of heavy-gauge wire (the “primary coil”). Following Faraday’s law, the rotating magnet creates an electric current (also called “flux”) that flows from the north pole of the magnet to the south pole, through that primary coil.

The primary coil is covered with special insulation, followed by about 18,000 turns of a very fine-gauge wire. This “secondary coil’s” job is to boost that original electric pulse that went through the primary coil to as much as 20,000 volts. When it reaches its peak strength (and timed perfectly with each cylinder), the breaker points are opened, releasing the high-voltage pulse to the distributor, which sends it down the wiring harness to the spark plug where ignition occurs. In a four-cylinder application, one complete rotation of the rotor sends a pulse to two of the cylinders in your engine, one after the other. It’s a beautifully timed and complex, yet simple, dance of electrons.

A New Twist

Our experts agree that there will always be a place for the lowly, but intensely reliable, magneto in the piston aviation world. In fact, research continues today to make the magneto even more efficient and reliable using new, advanced materials and new technologies. Champion and other aerospace ignition-component companies have also made great strides in improving the humble spark plug, with specialized copper cores and insulators made of innovative materials. “The system works, and works extraordinarily well,” agrees Christopher. “Nevertheless, we continue to evaluate new opportunities to improve performance and increase the reliability of our systems in order to add value for our customers.”

FADEC (full authority digital engine control) has completely changed the entire ignition system, relying on computers—and not magnetos—to time and generate the pulses going to the cylinders. Coming from the automotive world, FADEC introduces a new way to control the ignition system, allowing less pilot involvement, but adding greater cost, more hardware and complexity.

In addition to the standard magneto, Champion also offers the LASAR electronic ignition system that, unlike FADEC, still uses magnetos, but also electronically controls the timing of pulses and the entire envelope of engine performance through a microprocessor. This system monitors all kinds of critical engine parameters in real time and varies performance settings accordingly. In the event of a controller failure or loss of aircraft power, the system reverts to standard magneto operation. Though not yet significant in number, electronic ignition systems are slowly making their way into GA.

The most important thing to remember with regard to ignition systems is that they should be considered one of the most critical systems in the airplane. There are many resources to better understand how your aircraft ignition system works, and the University of North Dakota has put together an excellent animated “virtual” explanation of it on their website at www.undaerospace.com/cbt_files/virtualengine/Magneto/Virtual%20Engine.swf. Other great resources are available at the Champion Aerospace website (they acquired the Slick product line from Unison Industries) at www.championaerospace.com.